News

Direct electrospinning of cellulose in the DBU-CO2 switchable solvent system

02.06.2021

Mina Heidari, Kelechukwu N. Onwukamike, Etienne Grau, Stéphane Grelier, Henri Cramail, Michael A. R. Meier & Andreas Greiner

Cellulose 2021. https://doi.org/10.1007/s10570-021-03967-8

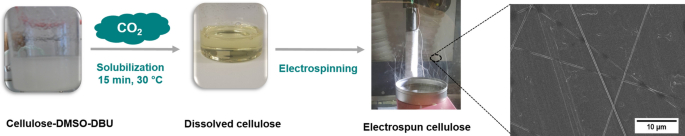

We report the use of the DBU-CO2 switchable solvent system for the direct electrospinning of cellulose. Two cellulose types were investigated, i.e. microcrystalline cellulose (MCC) and cellulose pulp (CP). The morphologies of the obtained cellulose fibers were studied using scanning electron microscopy and optical microscopy. Results obtained showed that only particles with mean diameter about 1.2 μm could be obtained when MCC was used, even at high concentration (10 wt%). In the case of CP, an optimized concentration of 4 wt% resulted in standing fibers with a mean diameter of about 500nm. In order to improve the spinnability of the cellulose, different concentrations and ratios of PVA in combination with cellulose were investigated. The combination of cellulose (both MCC and CP) resulted in the formation of a unique fiber morphology, characterized by a homogeneous bead-like structure. An in-depth study of the fiber structure was carried out using Raman spectroscopy and showed that both cellulose and PVA were present in the formed beads. Finally, the challenge observed remained a complete removal of the solvents, which are not volatile enough, as well as explore a coagulation collection process for the fiber recovery in order to recover and re-use the employed solvent.