News

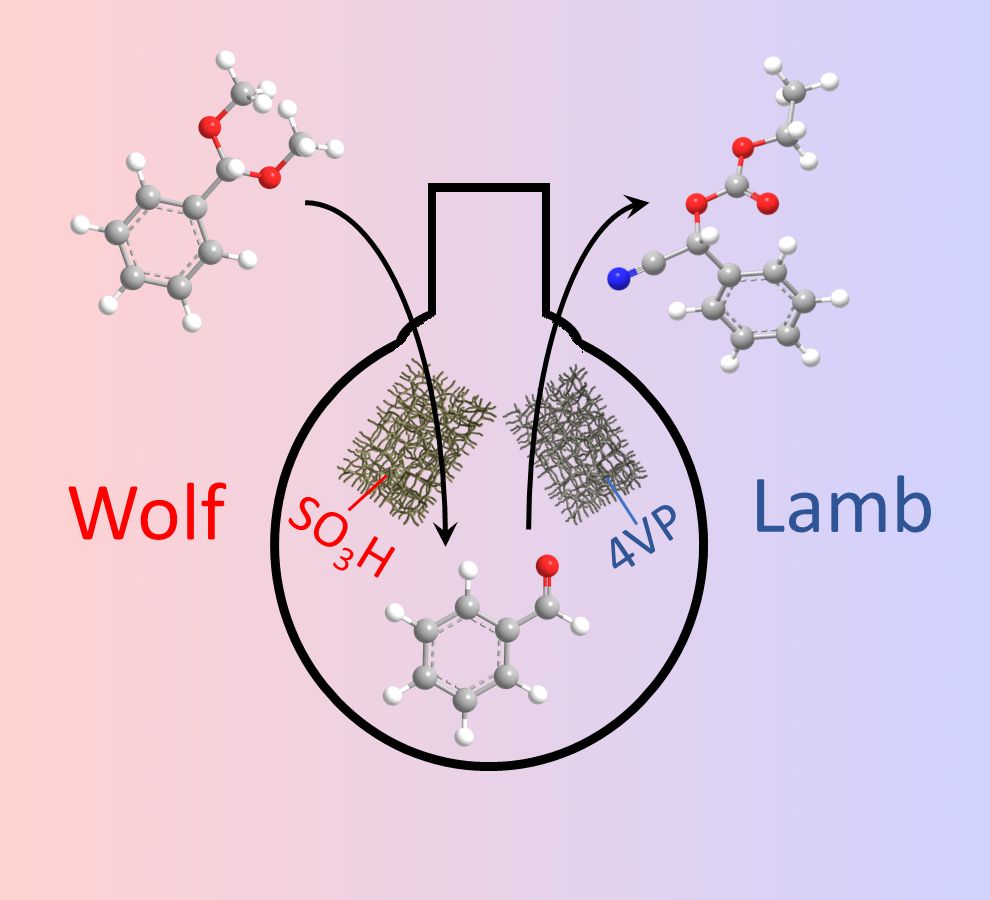

Wolf–Lamb-type Catalysis in One Pot Using Electrospun Polymeric Catalyst Membranes

09.05.2019

M. Pretscher, S. Gekle, S. Agarwal

Macromolecular Rapid Communication, 2019, 1900148

Multistep catalytic transformations using incompatible catalysts (Wolf–Lamb‐type) in a one‐pot reaction cascade require site isolation of different catalysts by compartmentalization. In this work, the use of different electrospun catalytic membranes in a modular way as individual compartments is shown for one‐pot Wolf–Lamb‐type reaction cascades. The data are presented for one‐pot cascade reaction sequences catalyzed by acidic and basic membranes made by electrospinning polymeric acid (poly(styrene‐co‐styrene sulfonic acid‐co‐4‐methacryloyl‐oxybenzophen)) and basic (poly(styrene‐co‐4‐vinylpyridine‐co‐4‐methacryloyl‐oxybenzophen)) catalysts, respectively. The two‐step, one‐pot system used is the acidic catalyzed deacetylation of dimethoxybenzylacetale to benzaldehyde, which reacts with ethyl cyanoformate to result in a high yield of product (over 90%) under base‐catalyzed conditions. The reaction kinetics are further monitored and evaluated by using differential equations, showing the necessity of a parameter Δt to represent a retarded start for the second reaction step. The concept provides an easy and upscalable approach for use in Wolf–Lamb‐type systems.